- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

The WL 6 single-shaft shredder has proven itself to be the classic shredder for wood waste of all kinds and is found in woodworking shops all over the world.

The popularity of this shredder series comes from is high level of reliability and competitive price.

These machines set themselves apart from other machines of their size and type due to their robust construction, giving them a longer life cycle.

Make an enquiry about the Weima WL 6 Shredder

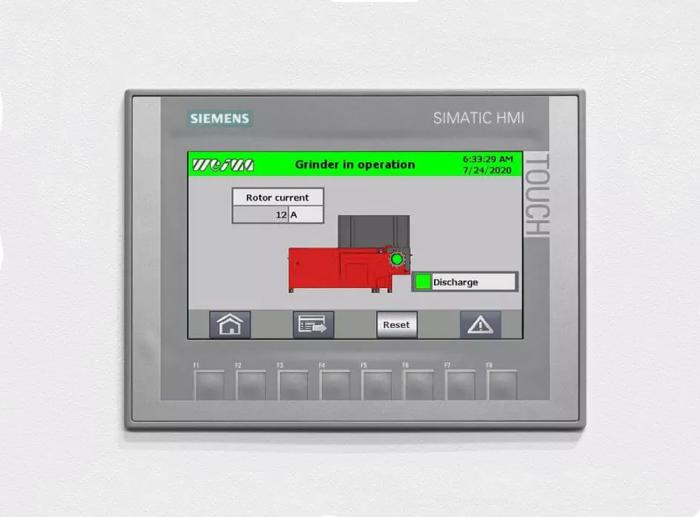

PLC control with touch display

Intuitive operation ensures that the electronics are optimally matched to the machine.

Weima design, build and wire their own control cabinets using only high-quality components, for example from Siemens or Rittal Intuitive touch interfaces guarantee quick adjustments and functions which are machine specific such as setting the ram cycle or stop ensure a high throughput. The built-in overload gives added protection.

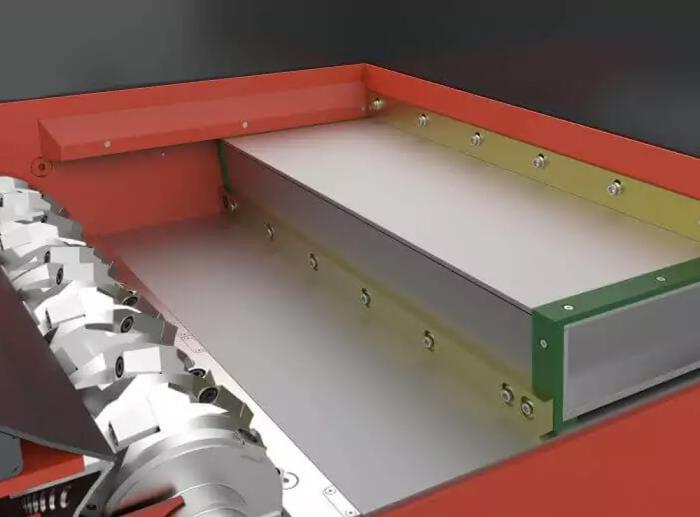

Profiled V rotor

Precise cut with high throughput with profiled V rotor.

The V rotor is specially developed by Weima, can be used universally and is made of solid material. Its aggressive material feed with up to two rows of knives guarantees a high throughput with low power requirements.

It can be equipped with hardened steel cutting knives in edge lengths of 30 mm and 40 mm. These can be turned over several times in case of wear, which drastically reduces maintenance costs.

Free-flow hopper design

The Intelligent designed hopper is rounded at the front and thus effectively preventing material bridges, the generous opening makes it easy to fill, even with bulky items the shredder can cut itself free and continue operating.

Powerful drive with Weima WAP gearboxes

Weima have been manufacturing their own WAP gearboxes in their German production facilities for many years.

The electromechanical drive via V-belt and powerful electric motor is also optimally protected against shocks and interference thanks to the built-in vibration damper. This counteracts increased wear and extends the service life of a machine.

Durable rotor bearings

Thanks to their offset design the rotor bearing are robustly designed to stand up to the stresses it is subjected to while in operation.

To prevent dust or foreign matter from getting inside it is set apart from the machine frame. This also makes it very maintenance-friendly and easy to access.

Interchangeable screen

Achieve consistent shredding results with the flexible, interchangeable screen

Adapt the screen to your needs. The smaller the hole diameter, the finer the shredded material that is discharged.

Safe material feed with load-controlled ram

The ram, which moves horizontally back and forth via hydraulics, feeds the material to the rotor, With Weima it can be controlled or cycled automatically depending on the load. If required, this can also be controlled manually.

Vibration-damping rubber feet

Efficiently absorb vibrations with stable rubber feet.

Vibration-damping machine feet ensure a secure footing and help to significantly reduce disruptive vibrations in the surrounding area.

Since the machine does not have to be anchored to the ground first, installation is particularly flexible and convenient.

| Dimensions (W x D x H) | 1.540 x 2.045 x 1.840mm |

|---|---|

| Weight | 1.700kg |

| Rotor Speed (rpm) | 80-125 |

| Rotor length | 800mm |

| Rotor Diameter | 260mm |

Specifications are subject to change without notice.

WL 6 Shredder

|

WL 600 Shredder

|

WL 4 Shredder

|

WL 8 Shredder

|

|

|---|---|---|---|---|

| Rotor Speed (rpm) | 80-125 | 80-125 | 80-125 | 80 -125 |

| Dimensions (W x D x H) | 1.540 x 2.045 x 1.840mm | 1.805 x 1.118 x 1.645mm | 1.190 x 2.045 x 1.640mm | 1.740 x 2.045 x 1.840mm |

| Weight | 1.700kg | 1.100kg | 1.300kg | 2,200kg |

| Rotor length | 800mm | 600mm | 600mm | 1000mm |

| Rotor Diameter | 260mm | 260mm | 260mm | 260mm |

Shredding + Compressing