- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

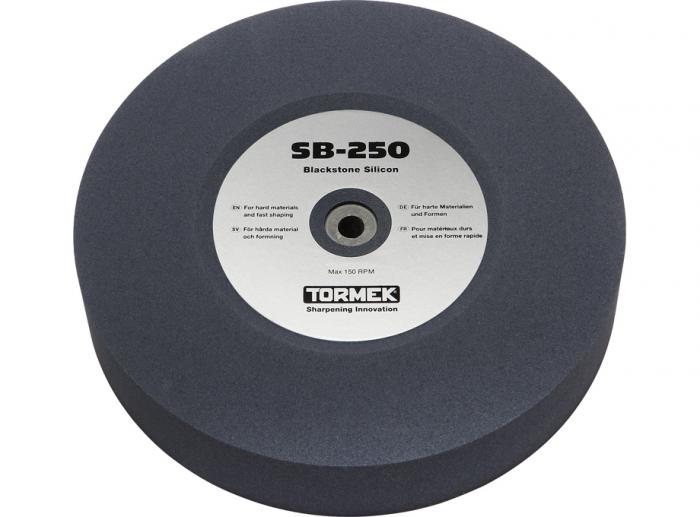

Tormek's Blackstone Silicon SB250 has been developed for shaping and sharpening* HSS and other exotic alloyed steels. It can also touch up tungsten carbide.

The combination of abrasive hardness, shape and grain size is optimised to work efficiently at the Tormek system’s low rpm. Its faster material removal is an advantage, especially when shaping tools with a large bevel surface, where the grinding pressure is limited; for example, planer blades and woodturning skews.

Make an enquiry about the Tormek SB250 Blackstone Silicone 250mm

The grit size 220 is the same as the Tormek Original Grindstone and can be altered to work like a 1000 grit stone with the Stone Grader SP650. Thanks to its sharp and relatively small grains, the Blackstone removes hard steel efficiently, even at low grinding pressure. The Blackstone Silicon also offers exceptional wear resistance. It can even touch up tungsten carbide, where the tool already has an established shape.

The SB250 does not offer faster steel removal on ordinary carbon steel than the Tormek Original Grindstone.

| Grit | 220-1000 (adjustable) |

|---|

Specifications are subject to change without notice.

SB250 Blackstone Silicone 250mm

|

SG250 Original Grindstone 250mm

|

SJ250 Japanese Waterstone 250mm

|

|

|---|---|---|---|

| Grit | 220-1000 (adjustable) | 220-1000 (adjustable) | 4000 |