- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

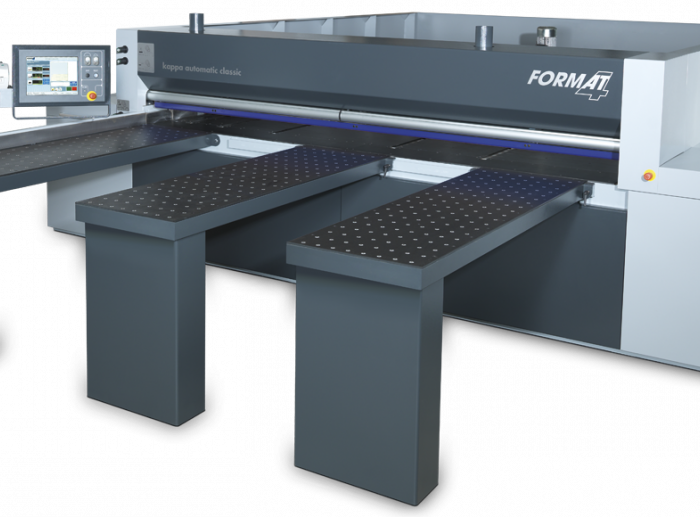

The compact beam saw for efficient cutting

The FORMAT4 kappa automatic beam saw fulfils the individual requirements of the discerning woodworker with efficient panel sizing with an excellent price/performance ratio, with a 2m² less space requirement than saws with the same cutting length.

The classic model convinces with the generous basic specification, with cutting lengths of 3,200 mm and 4,300 mm, two moveable support tables with air cushion function and a pressure device for an exact right angle cut when crosscutting. For perfect, chip free results, the main saw aggregate is equipped with a 7.5kW motor, has a max. 320 mm saw blade diameter and 68 mm saw blade projection. The intuitive touchscreen control concept ensures a quick and simple control of the machine.

Make an enquiry about the Format-4 Kappa Automatic Classic

Saw carriage

The saw carriage with main blade and scoring blade running on ground and hardened round guides ensures an extremely smooth movement and an exact cutting angle.

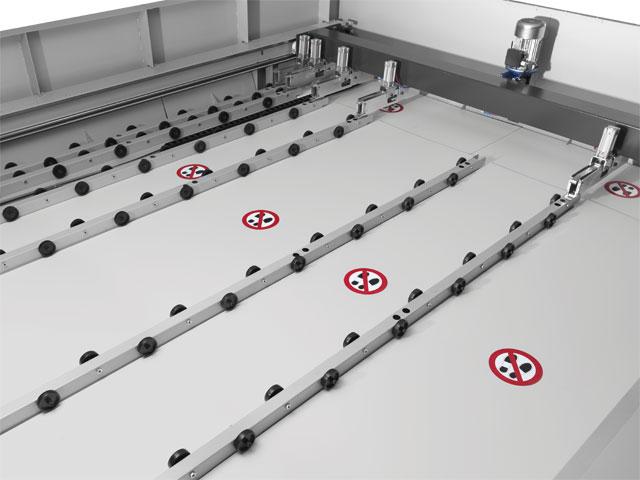

Roller track

The roller track supports the material pusher transport of panels and guarantees a precise feed of the panel material to the cutting line.

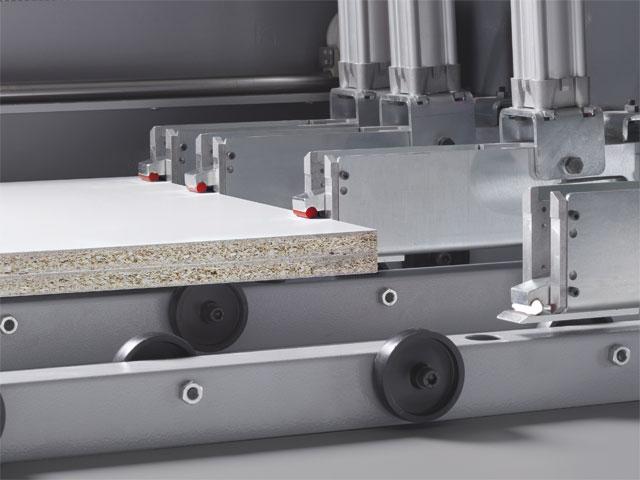

Work piece transport

Solid steel clamps, pneumatically controlled, guarantee a safe and damage-free clamping of panel stacks (opening height 80 mm) and individual small panels.

Double guided measuring system on the material pusher

The panel pusher, made from solid steel is guided on both sides and is equipped with a magnet measurement band system. The combination of a highly precise servomotor and solid material grips ensures maximum repeatability is achieved.

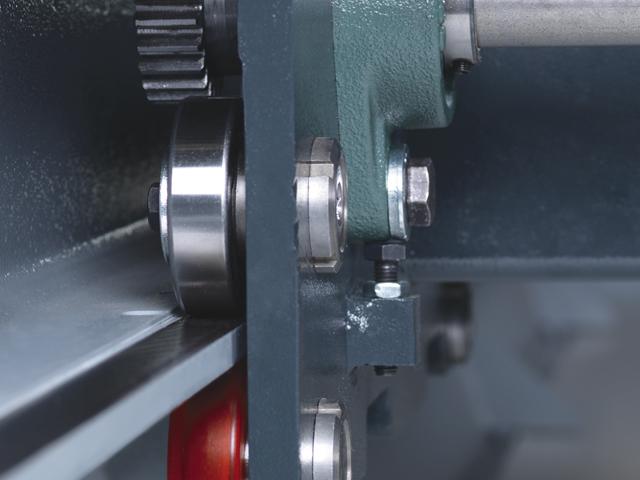

Saw carriage drive

The constant speed of the saw carriage is variable and can be set between 1–40 m/min from the control panel. The rack and pinion system on which the carriage runs guarantees a constant cutting quality regardless of the material being processed.

Pressure device

The pressure device with rollers presses the workpiece against the fence and guarantees an exact 90° angle (for workpiece widths 50–1200 mm).

Perfect process reliability

In combination with the cutting optimisation software a label can be printed for each workpiece with various information (order number, intended use, CNC program, which side is to be put through edgebander).

Simple operation

The simple design of the control panel and the clearly laid out menu guidance of the software control with a Windows based system, is intuitive in its operation. The kappa automatic can be equipped with Ardis cutting optimisation software. As an option, it can also be equipped with a label printer.

Pressure beam

The pressure beam lowers itself before making the cut and presses the workpiece onto the saw table. This pressure holds the workpiece during the cut and can be manually regulated up to max. 3 bar. The pressure beam also carries out the extraction of the dust and chips created by the saw blade.

Efficient software packages

The Format4 kappa automatic beam saw, guarantees simple operation and maximum efficiency with numerous software packages.

FORMAT4 Premium machines for premium requirements

Constantly high performance in industrial continuous operation

Customer specific optimised production solutions

Solid design with premium components

Many variations of specification packages with high-tech solutions

Complete engineering precision

Premium user comfort

Award winning design

Quality and precision from Austria

Uncompromised productivity

Perfect service package before, during and after the purchase

| Saw blade Ø | 320mm |

|---|---|

| Maximum cutting height | 68mm |

| Cutting capacity | 3200, 4300 mm |

| Motor | 7.5kW (10HP) |

| Feed speed | 1–40 m/min infinitely variable |

Specifications are subject to change without notice.

Kappa Automatic Classic

|

Kappa Automatic 140 Pressure Beam Saw

|

|

|---|---|---|

| Motor | 7.5kW (10HP) | 18kW (24.5 HP) |

| Saw blade Ø | 320mm | 450mm |

| Cutting capacity | 3200, 4300 mm | 3200mm, 3800mm, 4300mm, 5800mm |

| Feed speed | 1–40 m/min infinitely variable | 5–100 m/min infinitely variable |

| Maximum cutting height | 68mm | 118 mm |

Format-4 offer premium class woodworking machines from Austria. Part of the Felder Group.