- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

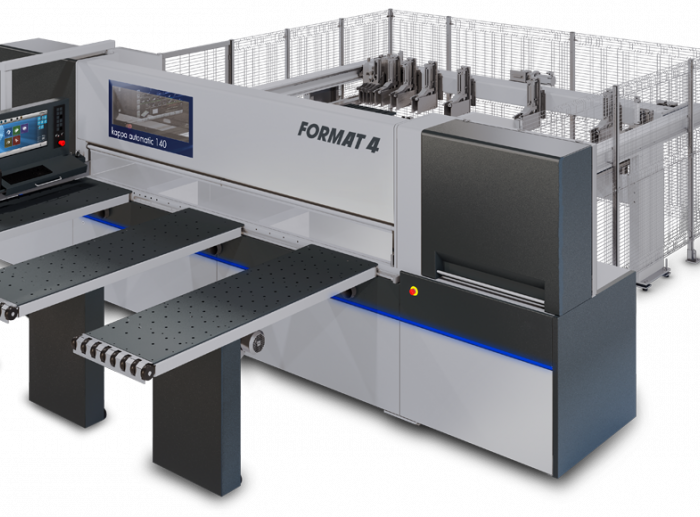

Powerful, precise and efficient, with heavy and massive saws, Format-4 relies on durable quality and first-class engineering. Right away, the kappa automatic beam saws impress with their elegant design and premium materials. It is also the full concept that convinces: The heavy-duty construction with steel pressure beam and material pusher, the simple operation even when working alone and maximum process reliability with the modularly structured cutting optimisation program as well as a new software package all guarantee maximum performance and precision in rational panel cutting.

The modular based cutting optimisation program with barcode labelling guarantees maximum process reliability. The saw carriage with main and scoring blade is guided along a hardened and ground round bar guide system. A highly precise gear drive and gear rack drive system results in an extremely smooth movement of the saw carriage with cutting speeds from 5 to 100 m/min. The high-end cutting edges are achieved by the automatic cutting height adjustment for the optimum saw blade entry angle and the smooth running of the saw carriage. The dual measuring system guarantees maximum repeatability. The pressure bar opens depending on the material height, which reduces the material movement times to a minimum. The "Green Line package" with its controlled extraction gates and direct control of the motors can reduce energy consumption by up to 30%.

Make an enquiry about the Format-4 Kappa Automatic 140 Pressure Beam Saw

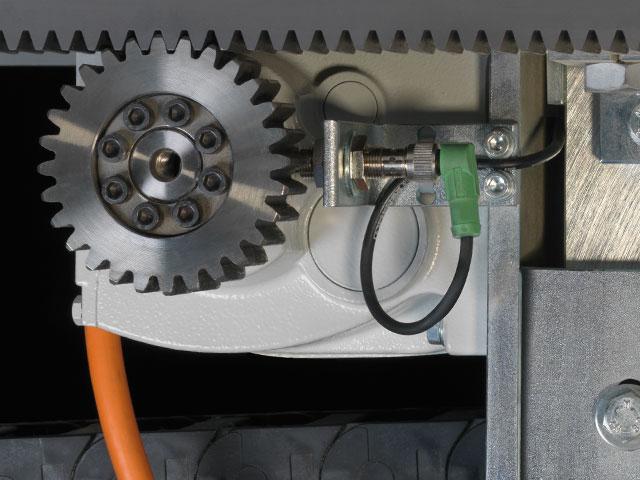

Saw carriage drive

The constant speed of the saw carriage is variable and can be set between 5–100 m/min from the control panel. The rack and pinion system on which the carriage runs guarantees a constant cutting quality regardless of the material being processed.

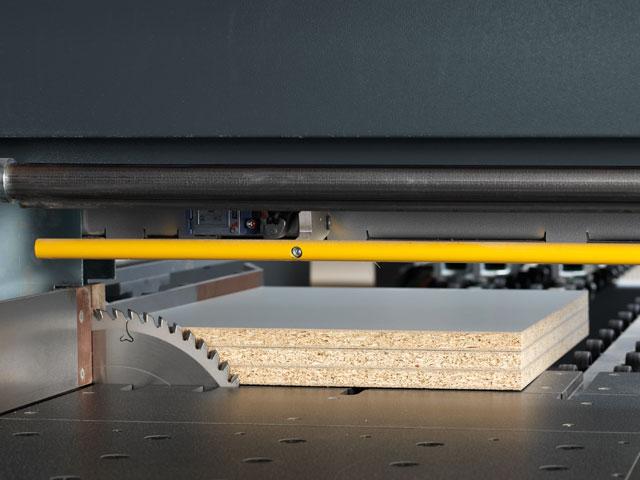

Perfect cutting results - New cutting direction

A main and scoring saw blade guarantee perfect and chip free cutting results with a cutting height of 80/100/118/138 mm. Combined with the cutting direction against the fence, a first class high end cutting result is achieved.

Controlled pressure bar - highest productivity with the shortest cutting cycles

The controlled kappa automatic 120 pressure bar does not open completely whilst processing, but instead only by the height of the material, enabling quick production cycles with maximum efficiency.

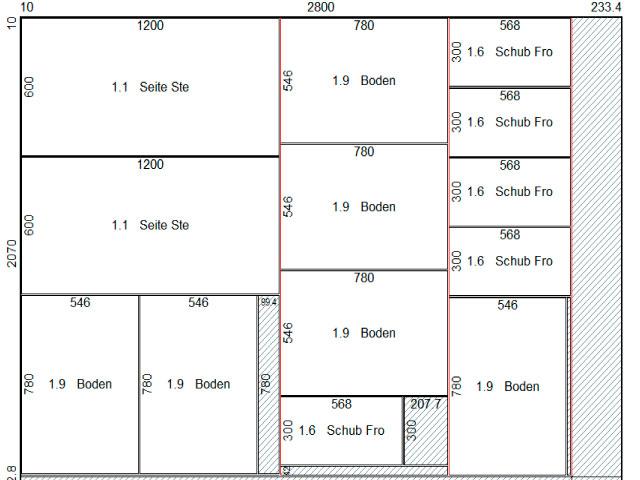

Cutting optimisation software

The modular cutting optimisation software uses the material list to calculate the most economic cutting process taking the cutting times and amount of waste into consideration. Compatible with the majority of construction and design programs it is also possible to calculate the amount of material and length of edge required, cutting times and/or be connected to a warehousing system with material administration.

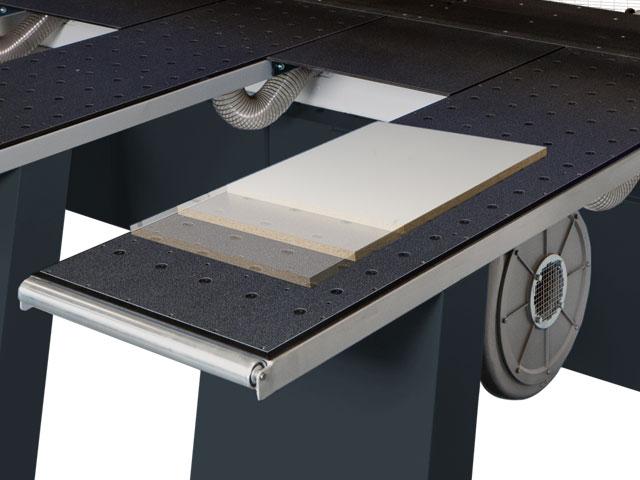

Effective loading using a lifting table_panel warehousing system

With the lifting table/panel warehousing system attached to the rear of the machine, it makes it possible to load the saw, panel by panel. The panels required can be loaded directly from the stack of panels onto the saw.

Cutting stacked panels

The saw blade projection of 55 or 80 mm in combination with a powerful drive unit offers the possibility to cut several stacked panels in one run which helps to increase production speed significantly.

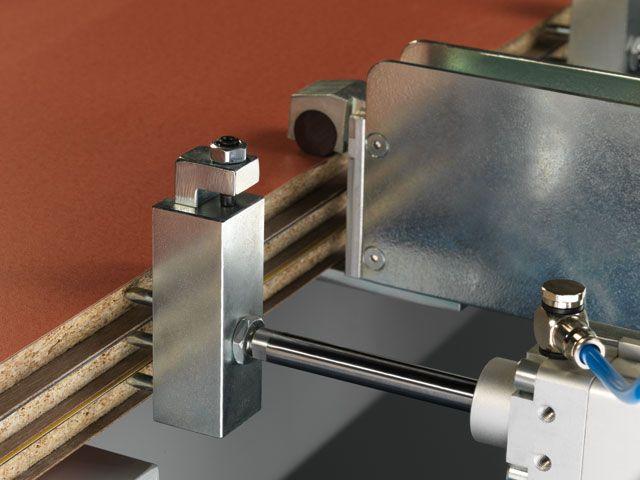

Pressure device

The automatic pressure device guarantees that the workpieces lie precisely against the mitre fence when cross-cutting (workpiece width 50–1200 mm).

Simple operation

The simple design of the control panel and the clearly laid out menu guidance of the software control with a Windows based system, is intuitive in its operation. Connecting the machine control to existing systems or networks is of course possible. The kappa automatic can be equipped with Ardis cutting optimisation software. As an option, it can also be equipped with a label printer.

Double measuring system on the material pusher

The material positioning unit is equipped with two measuring systems that constantly monitor each other. The combination of a highly precise servomotor and solid material grips ensure maximum repeatability. The measuring system is separate to the drive system and is completely free from wear and tear.

Perfect process reliability

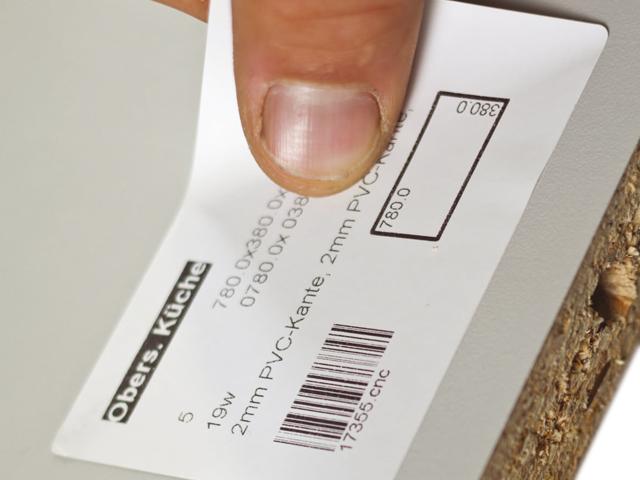

In combination with the cutting optimisation software a label can be printed for each workpiece with various information (order number, intended use, CNC program, which side is to be put through edgebander).

Package clamp double-finger version

Solid steel clamps, pneumatically controlled, guarantee a safe and damage-free clamping of panel stacks (opening height 90 mm) and individual small panels.

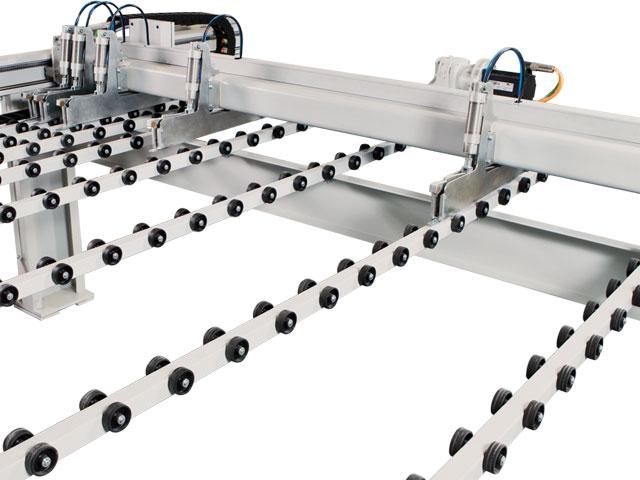

Roller track

The roller track supports the material pusher transport of panels and guarantees a precise feed of the panel material to the cutting line.

Material compatible handling

Unloading tables with air cushion technology guarantee a smooth handling of the material and a constant production flow especially when processing stacks of panels. Wheel conveyors situated near the material pusher ensure a gentle positioning of the material. For particularly pressure sensitive material the clamping pressure of the clamps can be adjusted using a manometer.

Veneer fences

Pneumatic veneer fences are available for panel cuts of veneered panel materials with a veneer projecting edge or laminated panels.

Polished machine table - better finish when processing sensitive materials

The polished machine table is particularly advantageous when processing sensitive materials and also offers an unlimited useable life.

Green Line Package - reduces production costs and noise emissions

The Green Line Package available for the kappa automatic models reduces the extraction volume required by up to 30% through a controlled extraction gate on the pressure bar. Additionally the motors use up to 30% less energy due to the reduced travel time after the cut. With a certified noise emission of only 73.5 dB one of the quietest beam saws in its class

FORMAT-4 Premium machines for premium requirements

Constantly high performance in industrial continuous operation

Customer specific optimised production solutions

Solid design with premium components

Many variations of specification packages with high-tech solutions

Complete engineering precision

Premium user comfort

Award winning design

Quality and precision from Austria

Uncompromised productivity

Perfect service package before, during and after the purchase

Automation solutions

Software and machines from a single supplier

| Saw blade Ø | 450mm |

|---|---|

| Maximum cutting height | 118 mm |

| Cutting capacity | 3200mm, 3800mm, 4300mm, 5800mm |

| Motor | 18kW (24.5 HP) |

| Feed speed | 5–100 m/min infinitely variable |

Specifications are subject to change without notice.

Format-4 offer premium class woodworking machines from Austria. Part of the Felder Group.