- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

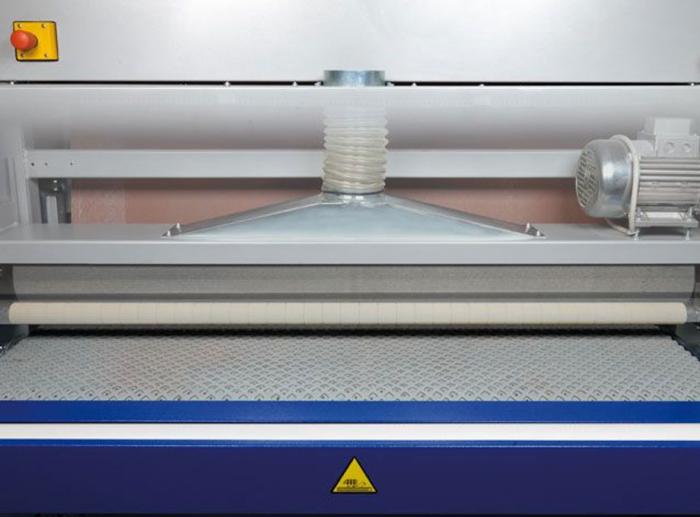

An outstanding choice if you are looking for a perfect workpiece finish!

Beneath perfectly laquered, stained or oiled wood surfaces, there is always a perfectly polished area. Felder Group wide belt sanders are set apart by their solid, sturdy construction, the latest machine technology and maximum productivity.

A large variety of machine types, sanding units and options makes it possible to adapt each machine to your specific needs. This makes Felder Group Wide Belt Sanders the number 1 choice when your wood surface "finish" needs to be absolutely perfect.

Please note machine images may show optional equipment

Make an enquiry about the Format-4 Finish 1102 Wide Belt Sander

Variable feed speed adjustment

As standard the feed speed can be continuously adjusted from the control panel between 2.8–20 m/min.

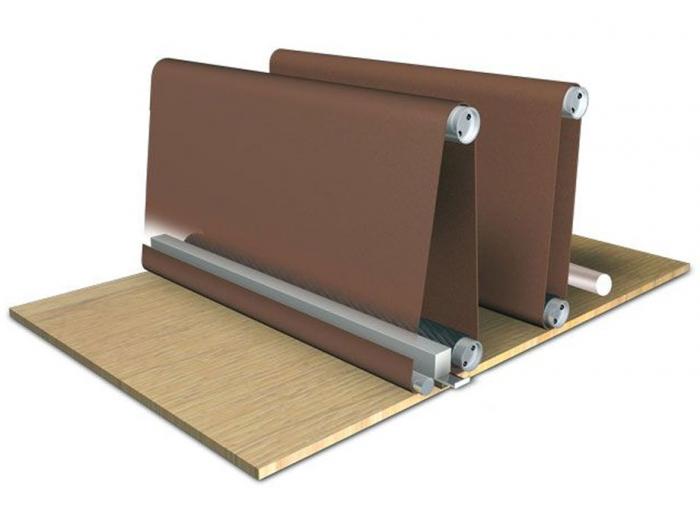

Combination module with electro-pnuematic sanding pad

With a contact roller unit with rubber contact roller (85 shore) for calibration work, an electro-pneumatic sanding shoe for fine work and veneer work, the combination module with electro-pneumatic sanding pad is used to machine solid wood and for veneer work.

Upon initiation of the sanding process, the electro-pneumatic sanding pad is lowered 1/10 mm onto the workpiece. This avoids the risk of penetrating the veneer at the front and rear of the workpiece. The guidance system is steered by a distance trigger and impulse counter system. The pulse counter regulates the movement of the sanding pad depending on the feed rate.

Clearly structured control panel

The clearly structured and intuitively laid out control panel offers the greatest ease of use and maximum productivity. The machine functions are displayed graphically and controlled by high-quality switches. The infeed thickness is displayed as an overview on the digital display and can be adjusted in increments of 0.1 mm using the push button.

Depending on your configuration, a touchscreen control is also available. (Both are shown)

Automatic thickness measurement

With the automatic thickness measurement function no additional gauges are required to measure the workpiece thickness as it can be measured directly on the machine. The desired depth of cut can be pre-selected on the adjusting handwheel, with +ve and –ve settings possible.

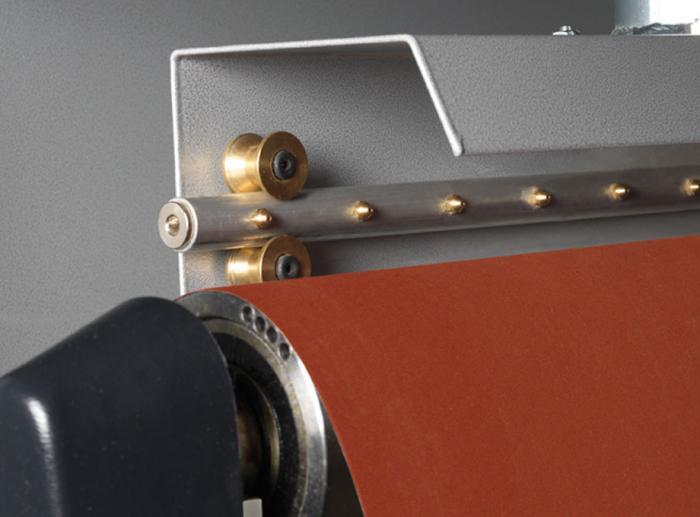

Belt guidance system

The belt guidance system scans the workpiece using a modular spotlight and activates the electro-pneumatic belt guidance, which moves the belt fowards and backwards.

In addition, safety switches monitor the sanding belt speed. If there is a risk that the sanding belt runs off course the belt speed control stops the sanding belt motor immediately.

Brushing equipment (option)

As an option, on the delivery side of the machine it is possible to set up a brushing facility. Different brushes can be inserted to clean, polish or structure the workpiece surface.

A blow-off facility (option)

The blow-off facility is necessary when grinding lacquered workpieces. It cleans the sanding belt exceedingly well and this as a result, prolongs the lifespan of the sanding belt.

In-feed and out-feed tables (option)

If required we are able to equip your Format-4 wide belt sander with roller extension tables both on the in-feed and out-feed side.

Infinitely variable speed (option)

The infinitely variable (sanding) belt speed is required specifically to sand lacquered surfaces. This detail increases the operational use of your wide belt sanding machine. The sanding belt speed can be adjusted continuously from 2.4 to 19 m/min.

Pneumatic selection of the contact rollers (option)

With this option, the contact rollers can be engaged or released via the control panel. In combination with the storable programs, the flexible operational application of the machine is made even easier.

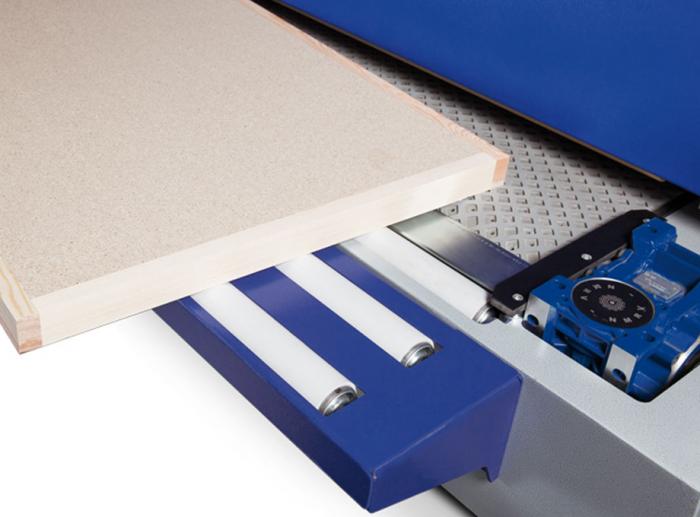

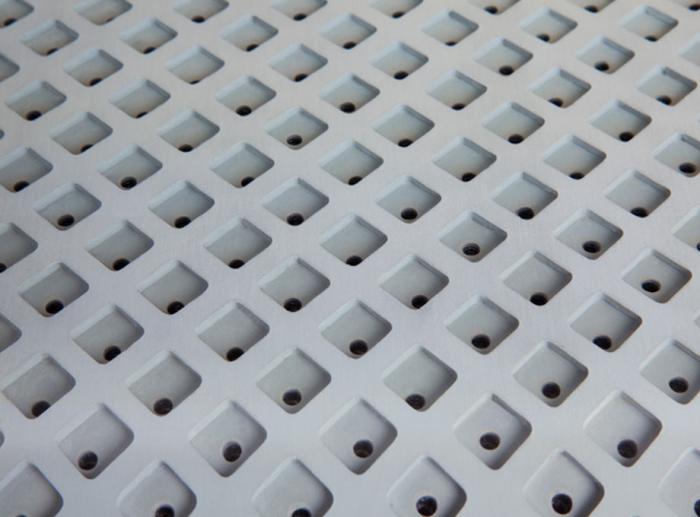

Vacuum table (option)

A vacuum table is available as an option for very smooth, small and thin work-pieces. The vacuum is created by a high pressure air blower coupled to the feed table.

When the blower operates, a vacuum is created in the cavities of the feed table. This vacuum then acts on the workpiece through the holes in the vacuum feed mat.

| Working height | 3 - 170mm |

|---|---|

| Working width | 1100mm |

| Motor | 11kW (15hp) |

| Feed speed | Variable from 2.8 - 20m/min |

| Dust extraction | 2 x 160mm |

| Sanding belt size | 1110 x 1900mm |

| Weight | 2120kg |

Specifications are subject to change without notice.

Finish 1102 Wide Belt Sander

|

FW1102 Classic Widebelt sander

|

FW950 Classic Widebelt Sander

|

|

|---|---|---|---|

| Working width | 1100mm | 1100mm | 950mm |

| Working height | 3 - 170mm | 3 - 170mm | 3 - 170mm |

| Sanding belt size | 1110 x 1900mm | 1110 x 1900mm | 970 x 1700mm |

| Dust extraction | 2 x 160mm | 2 x 160mm | 1 x 120mm |

| Motor | 11kW (15hp) | 15kW (20hp) | 7.5kW (10hp) |

| Weight | 2120kg | 1150kg | 800kg |

| Feed speed | Variable from 2.8 - 20m/min | Variable from 2.5 - 10m/min | Variable from 2.5 - 10m/min |

Format-4 offer premium class woodworking machines from Austria. Part of the Felder Group.