- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

Thicknessing is the toughest task in most shops and needs a strong machine. These are built to last.

- Solid cast iron table extensions ensure excellent workpiece support

- Two adjustable rollers in table bed assist with feeding of moist or resinous timber

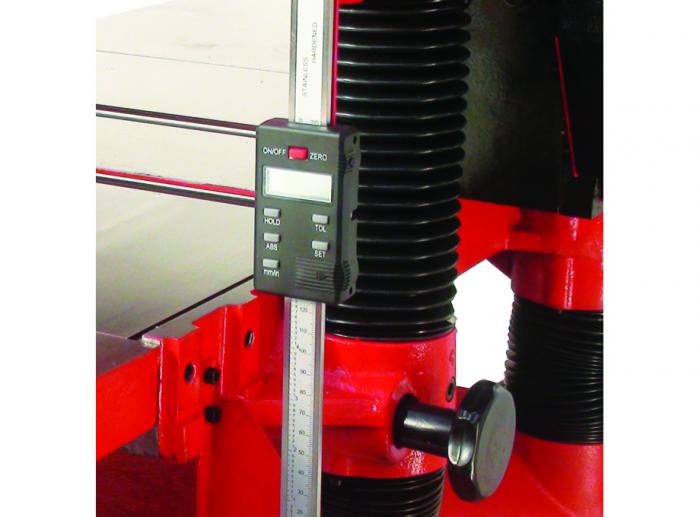

- Digital display for thickness setting provides repeatable accuracy to 0.1mm

- Four post table support ensures high stability

- Big 200mm thicknessing capacity

Some assembly required.

Make an enquiry about the Ascent Machinery TH500 Thicknesser

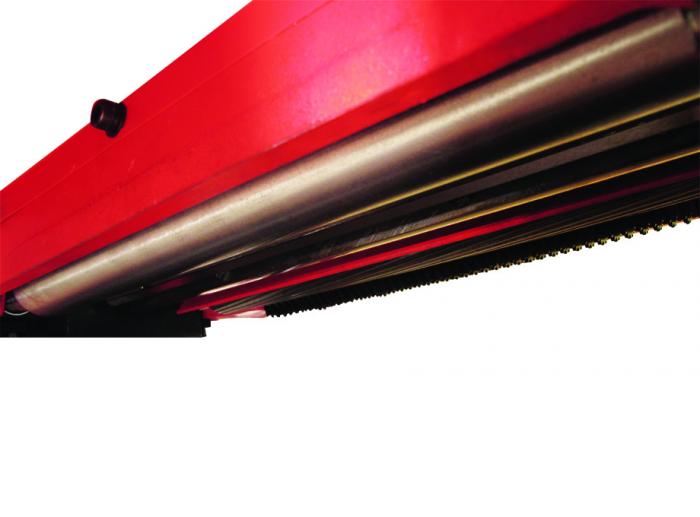

Chrome steel infeed and outfeed rollers.

Strong steel anti-kickback fingers to protect the operator. Spiral toothed infeed roller ensuring the grip is never relaxed. Spring loaded infeed pressure bar prevents bouncing and vibration. Smooth steel outfeed roller, for a flawless finish. No rubber or neoprene coating to get damaged and worn.

Large extraction hood to improve extraction.

The dust port is angled to side, giving efficient chip removal and keeping ducting clear of the work return rollers.

Digital read-out as standard.

Jacks includes digital height display as standard. No more messing around with test pieces because you can't read the lineal scale accurately. The digital display provides repeatable accuracy to 0.1mm.

Numerical setting is quick and accurate - great for jobbing work which has to match existing material.

| Motor | 2.2kW (3hp) 1 phase; 3.7kW (4.9hp) 3 phase |

|---|---|

| Cutterblock Ø | 78mm |

| Cutterblock speed | 5000rpm |

| Feed speed | 4.9 - 6m/min |

| Knives | 4 |

| Thicknessing width | 508mm |

| Maximum workpiece thickness | 204mm |

| Maximum stock removal | 6mm |

| Weight | 370kg |

Specifications are subject to change without notice.

Ascent Machinery is available exclusively from Jacks.

Our warranty policy is second to none, and applies to every machine we sell. We're so proud of this policy that you can read it here on our website. We strongly recommend you compare it with others before you buy elsewhere.

Ascent Machinery is exclusive to Jacks