- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

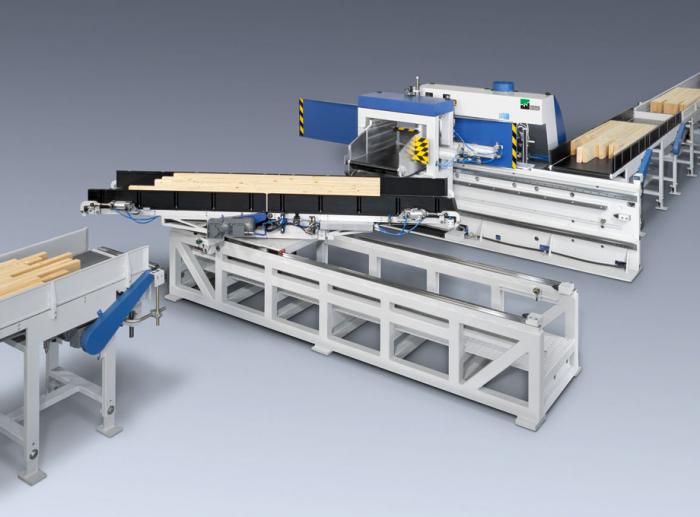

Grecon's Ultra Series of finger jointing lines offers versatility and value.

The Compact Ultra finger jointing series offers all the benefits of Weinig’s advanced techniques, capacity and plenty of flexibility. With its onboard, optionally manual or automatic turntable, it is the perfect solution for the economical utilisation of residual wood.

Make an enquiry about the Weinig Ultra Series Finger Jointer

State of the art technology

The shaping unit cuts the finger joints into the the face of the package of timber. After rotating, the joint is cut into the second face - after the cutter spindle has automatically shifted by one half finger to ensure a precise joint.

Exact glue application

Following the second cutting process, the exact required amount of glue is applied via the patented Flakenjet process. The profiled and glued timber pieces are fed into the hydraulic press with integrated saw, cut to length and then pressed.

Manual or Auto turntable

The Ultra TT model makes use of an automatic servo-turntable, increasing performance by up to 40%.

| Motor | 22kW (29.5hp) |

|---|---|

| Minimum workpiece length | 150mm |

| Minimum workpiece width | 40mm |

| Feed speed | 15.2m/min (Vertical joint) |

| Maximum workpiece thickness | 80mm |

Specs shown are for a standard model, but Weinig offer a wide variety of options, so talk to us about customising a machine to suit you.

Specifications are subject to change without notice.

Visit Weinig's youtube channel >>

The whole world of solid wood processing with Weinig