- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

Build Quality

Heavy duty frame construction. Twin 260 x 160 x 8mm thick steel beams form the foundation of the machine frame.

Precision CNC robotic welded, heat treated to 590 ° C then machined on a 5 axis CNC to guarantee maximum accuracy for positioning components.

Performance

Superior 8mm thick steel gantry design dampens vibration. Driven on both sides by independent servo motors with absolute encoders. Eliminates gantry flex while maintaining repeatable accuracy. Positioning speed in X & Y axis of 100m/min.

100% Quality

Only the highest quality components go into every KDT CNC. Taiwanese PMI helical rack & pinion with German robotic flexible cables ensure performance you can rely on.

Ease of Use

Use of the latest software and operating systems provide a modern, user-friendly interface for the CNC operator. Automatic central lubrication, automatic gated extraction and monitored pop-up rails and stops ensure a safe and comfortable working environment.

Heavy Duty Gantry (HDG)

8mm thick steel gantry with 1.5KW servo motors on both sides providing positioning accuracy and fast acceleration and deceleration.

Powerful 9KW (12HP) Main spindle

Plenty of power for almost any job.

Twin X Axis Servo Motors

Prevents “racking” of gantry and increases processing accuracy.

Industrial Controller & Windows 10 OS

Proven industrial CNC controller with Microsoft 10 operating system.

Modular System

Add auto labelling, loading and unloading units to increase productivity and efficiency

Make an enquiry about the KDT KN-2409DL

Main spindle 9kW (12HP)

The main spindle is connected to the Z-axis plates and guided with 2 lineal guides. Z-axis movement with large diameter ball screw.

The tool is clamped with ISO-30 connection. The tool holder connection is monitored to maximise safety.

• Connected load: 9kW (12HP) • Spindle rotation speed: 3000 - 18000 rpm • 4-way air blower to significantly improve dust extraction performance • Bearing: ceramic bearings • Spindle cooling: air-cooled • Supplied with 12 tool holders

DH10 drilling head

Vertical drilling unit with 10 vertical drilling spindles. 6 spindles in the X direction and 4 in the Y direction.

• All drilling spindles can be used individually or in combination • All drill spindles can access the full width and length of the working table • Rotation speed 6000rpm

Automatic length measurement systems for tool in Z axis

No manual tool measurement required.

The tool will be measured whilst in the machine to provide an exact tool length. The length of the tool will be automatically transferred and saved to the tooling database.

The Z axis stroke will compensate for the tool length so that the exact milling depth is achieved.

12 Position linear tool magazine

The linear tool changer is conveniently tucked under the gantry and travels along the X axis with the gantry.

This reduces the time required to change tools as the gantry does not need to travel back and forth to a fixed tool magazine when changing tools.

Control terminal for machine operation

Clear and easy to understand interface for machine operation and singular piece programming. Includes handheld remote for testing programs and prototyping. • Mobile control terminal • Windows 10 Operating System • 1 USB port

Vacuum system

A Eurovac vacuum pump with a total vacuum performance of 250 m3/h at 50 Hz is supplied as standard with the KDT KN-2409DL CNC.

The vacuum pump combined with the multi grooved phenolic matrix table and efficient under table vacuum plumbing system, ensure workpieces are held firmly in position.

• 250 m3/h vacuum capacity

A control sensor for the vacuum suction level avoids the risk of components moving during processing and potentially being projected into the workshop.

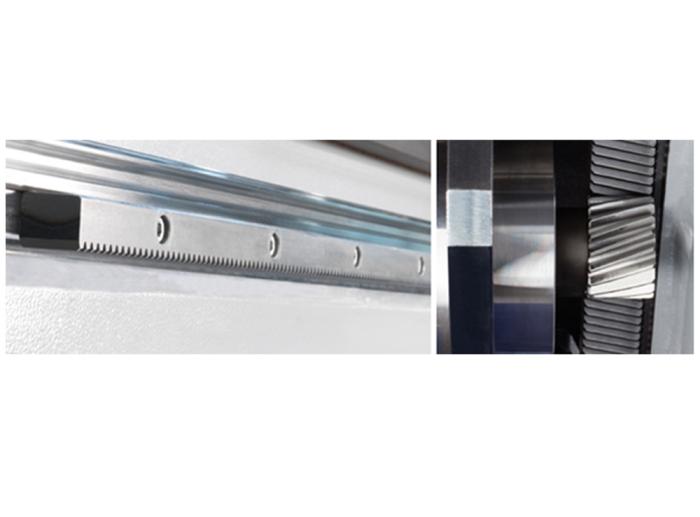

Guiding system X & Y Axis

Gantry movement along the X and Y axes is carried out through a 30mm helical rack and pinion system with high precision lineal guides.

Helical rack and pinions ensure rack teeth are always fully engaged. Delivering smooth acceleration and deceleration with increased positioning accuracy.

Vacuum pusher arm

Use the vacuum pusher arm to clean the spoil board between processing sheets. Can also be used in combination with the (optional) outfeed conveyor table to automatically unload the machining table.

Also supplied with suction cups & side panel alignment pusher for connection to (optional) automatic loading table.

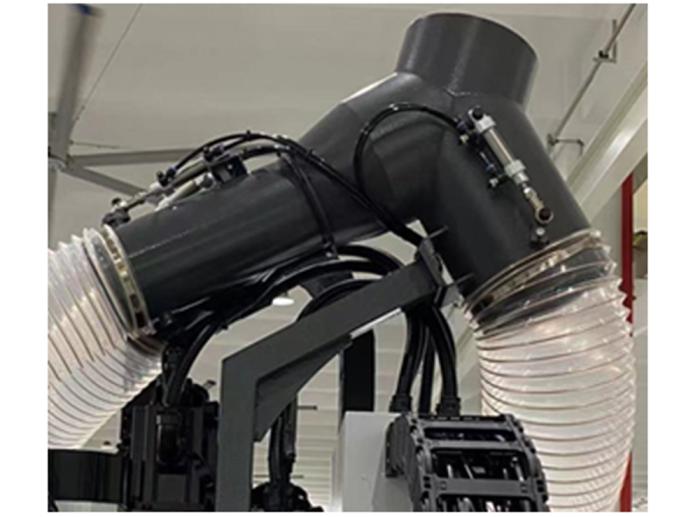

Automatic extraction gate system

The automatic extraction gate system closes the non-required chutes focusing the extraction airflow to the required port. 2 independent extraction chutes with automatic gates. 1 for the main spindle 1 for the vacuum pusher 1 x 150mm main extraction port connection Air volume required 2800m3/h at 25m/sec (class leading)

| Table size | 2850mm x 1220mm |

|---|---|

| Dust extraction | 150mm |

| Drilling head | 10 Spindles |

| Main spindle | 9kW |

| Vacuum | 250m³/h |

| Weight | 2500 kg |

Specifications are subject to change without notice.

Calder Stewart with the new KDT

Jamie Harding from Keith Paton Joinery with his new WDMAX CNC

Alternatives Manufacturing WDMAX CNC

Intech Designer Kitchens and their WDMAX

A world leader in CNC & Edgebanding production