- Products

- Saws

- Edgebanding

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

The WLK 4 single-shaft shredder is ideal for processing almost all plastics as well as hard and resistant materials. These machines can shred plastic lumps, pipes, blow molded materials like PET bottles, PE/PP bottles, canisters, buckets, paper products, cardboard, and light metals.

Make an enquiry about the Weima WLK 4 Shredder

Free-cutting hopper design

No material bridges due to free-cutting hopper design.

The hopper fulfills several tasks at once. First, the material to be shredded is fed through it – manually, mechanically, or by conveyor belt. The generous opening makes it easy to fill even very large parts. A decisive factor for shredding, however, is its special design, which is rounded at the front and thus effectively prevents material bridging.

Even with bulky parts, the shredder cuts itself free. If required, hopper extensions and lids with gas pressure springs are available.

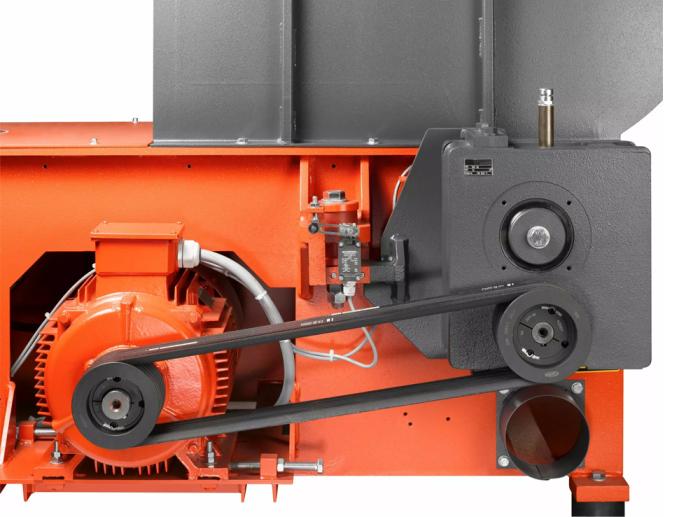

Powerful drive with Weima WAP gearboxes

Weima have been manufacturing their own WAP gearboxes in their German production facilities for many years.

The electromechanical drive via V-belt and powerful electric motor is also optimally protected against shocks and interference thanks to the built-in vibration damper. This counteracts increased wear and extends the service life of a machine.

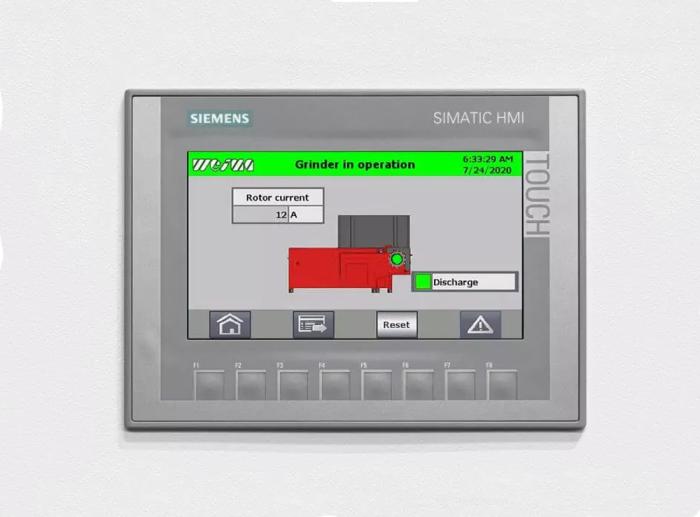

PLC control with touch display

Intuitive operation ensures that the electronics are optimally matched to the machine.

Weima design, build and wire their own control cabinets using only high-quality components, for example from Siemens or Rittal Intuitive touch interfaces guarantee quick adjustments and functions which are machine specific such as setting the ram cycle or stop ensure a high throughput. The built-in overload gives added protection.

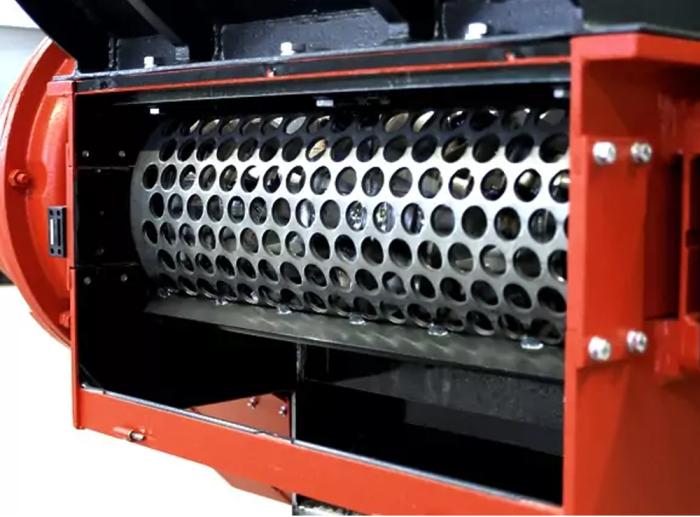

Profiled V rotor

Precise cut with high throughput with profiled V rotor.

The V rotor is specially developed by Weima, can be used universally and is made of solid material. Its aggressive material feed with up to two rows of knives guarantees a high throughput with low power requirements.

It can be equipped with hardened steel cutting knives in edge lengths of 30 mm and 40 mm. These can be turned over several times in case of wear, which drastically reduces maintenance costs.

Interchangeable screen

Adapt the screen to your needs. The smaller the hole diameter, the finer the shredded material that is discharged. Screens can be exchanged flexibly and are bolted as standard.

Durable rotor bearings

Thanks to their offset design the rotor bearing are robustly designed to stand up to the stresses it is subjected to while in operation.

To prevent dust or foreign matter from getting inside it is set apart from the machine frame. This also makes it very maintenance-friendly and easy to access.

Vibration-damping rubber feet

Efficiently absorb vibrations with stable rubber feet.

Vibration-damping machine feet ensure a secure footing and help to significantly reduce disruptive vibrations in the surrounding area.

Since the machine does not have to be anchored to the ground first, installation is particularly flexible and convenient.

| Dimensions (W x D x H) | 1.313 x 2.045 x 1.685mm |

|---|---|

| Weight | 1.700kg |

| Rotor Speed (rpm) | 80-125 |

| Rotor length | 600mm |

| Rotor Diameter | 260mm |

Specifications are subject to change without notice.

Optimally protected hydraulics installed in the machine frame

Integrating the sensitive components of a hydraulic system into the machine frame has many advantages. Not only is it protected from dust, dirt and other external influences such as the weather, but it also makes the machine even more compact in its installation. A separate service opening provides easy access for maintenance.

Clean discharge of material by suction, screw or conveyor belt

Depending on your needs and frame design (elevated machine with conveyor belt cutout or side spout), you have the option of discharging shredded material either by air suction, discharge screw or classic conveyor belt. With experience from many thousands of machines on the market, we are also experts in conveyor technology and can supply you with a turnkey solution from a single source.

Shredding + Compressing